Designers involved in product development often face several complex choices. Each manufacturing method requires a detailed understanding of its capabilities and constraints. The focus must always remain on compatibility between design intent and production feasibility. Making informed selections early can improve efficiency across the entire development cycle.

One option that emerges in specific design cases is Rubber Compression Molding. It is selected based on part shape, production scale, and available tooling resources. This article explores six essential considerations every product designer should keep in mind.

1. Suitability of Part Geometry

Certain geometries align more naturally with the compression method. Flat or slightly contoured parts provide better mold coverage and avoid material build-up. Smooth profiles encourage even material distribution, minimizing the risk of air pockets or incomplete shapes. Rounded edges and uniform dimensions support uninterrupted flow during the pressing phase.

Designers should consider whether the part can retain performance with fewer intricate features. Gradual transitions and consistent wall thickness improve molding accuracy and reduce material resistance. Selecting streamlined profiles supports a more controlled and predictable molding operation.

2. Characteristics of the Material

Different rubber materials react uniquely to applied pressure and heat during the process. Some formulas offer high flexibility, while others maintain strength under compression. Thermal resistance, shrinkage behavior, and flow characteristics should meet design demands. The selected material must also remain stable throughout repeated cycles.

Choosing a compatible rubber compound depends on the part’s intended function. Heat, chemicals, or pressure exposure will influence how long the material remains stable. Early testing or consultation with compound specialists helps ensure the selection supports the production method. Material performance affects every stage, from molding to end use.

3. Production Volumes and Scheduling

Each manufacturing technique more efficiently supports specific volume goals. Compression molding is generally aligned with projects requiring medium or lower batch runs. Quick mold adjustments and moderate setup requirements allow flexibility for customized or evolving product lines.

Timelines and batch sizes often determine the right match. High-volume manufacturing may demand different approaches with faster cycles. However, compression can meet production needs for limited runs or specialty items without the overhead of more complex systems. This flexibility becomes valuable during testing, refinement, or seasonal product rollouts.

4. Design Timelines and Overall Coordination

Coordinating development with manufacturing resources ensures steady progress. Mold fabrication, cure testing, and design feedback cycles contribute to the final product schedule. A structured timeline helps reduce waiting periods between testing and revision stages. Aligning internal teams around delivery targets avoids project slowdowns.

Compression molding supports streamlined coordination for low-to-mid-scale projects with evolving design criteria. Flexibility in tooling changes can help adapt to design updates without starting over. Efficient planning ensures that resources are used appropriately across all phases.

5. Tolerance and Dimensional Control

Maintaining predictable dimensions is essential when parts must interact with others. Compression processes can create slight shifts in shape due to heat and pressure variability. Pre-shrinkage calculations and cavity design play a large role in maintaining measurement stability.

It is critical to consider the acceptable tolerance range for each part. Slight adjustments in the mold or post-processing methods can correct minor variations. Designers must define these tolerances clearly during the drawing phase to prevent misalignment during assembly. Dimensional allowances should reflect the function and performance expectations.

6. Tooling Layout and Mold Preparation

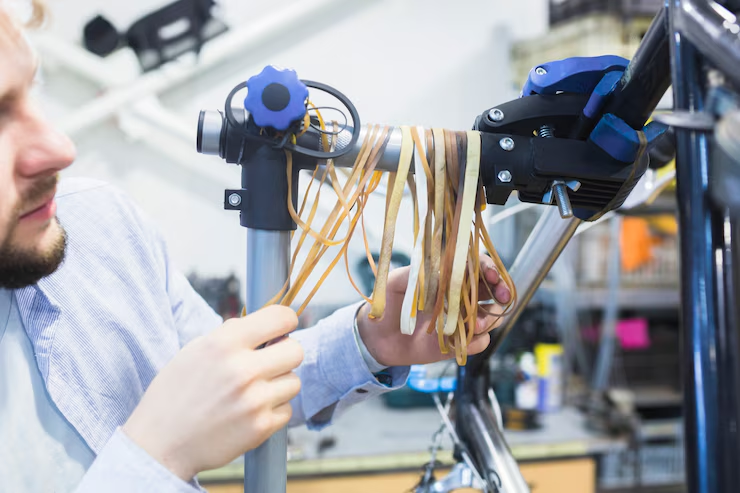

Tool design directly affects the performance of the entire molding sequence. Compression molds require uniform heat distribution and can apply equal force across the cavity. Any imbalance may result in uneven parts or excess material outside the final shape. Each tool must be reviewed for thermal consistency. Key tooling features can support smoother production and longer mold life when incorporated correctly:

- Clear tooling layout reduces unnecessary mold wear over time

- Balanced pressure application promotes consistent part formation

- Strategic vent placement prevents defects from trapped air or material buildup

- Consistent cavity temperature helps maintain surface quality during production

- Defined tolerances assist in aligning parts correctly during assembly

Partnering with Specialists for Technical Precision

Designers often benefit from working with facilities that have extensive experience in custom rubber molding. When precision, material compatibility, and production efficiency are critical, access to ISO-certified products and hiring knowledgeable engineering support are essential. These environments typically provide detailed guidance on mold construction, compound selection, and process adjustments.

Facilities that handle standard and complex molding applications often maintain tight quality controls and flexible production capabilities. Their ability to support low- to mid-volume runs while maintaining material integrity and dimensional accuracy adds value to the design process. Engaging with such teams allows product developers to focus on performance while maintaining production continuity.

Rubber Compression Molding begins with understanding part geometry, material properties, volume expectations, and mold planning. When aligned with design goals and manufacturing realities, it delivers consistent results. When applied with thoughtful consideration and clear execution, this product supports streamlined production. Every design decision made upstream contributes to a smoother process downstream.