What determines strength and durability in industrial connections? How do engineers ensure stability in high-torque settings? These questions often lead to one critical component: Screw Top. Known for their precision and holding power, they offer reliable fastening in many mechanical and structural settings.

Understanding the Basics

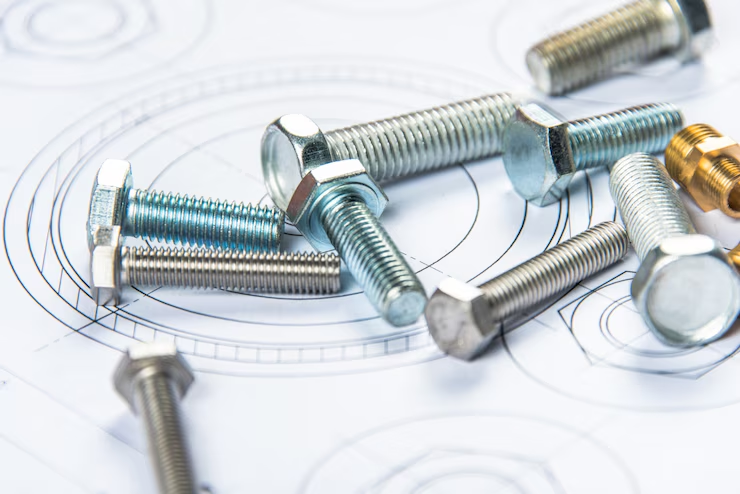

Cap screws are manufactured with precise tolerances to ensure a secure and accurate fit in assemblies. Their finished appearance makes them suitable for applications where both functionality and aesthetics matter. These fasteners are widely used across industries, including automotive engines, heavy machinery, and industrial equipment, due to their strength and reliability.

The threaded shaft allows for firm fastening, while the variety of head designs—such as hex, socket, and button heads—provides flexibility to meet different installation requirements. This adaptability makes them a preferred choice for projects demanding durability, alignment, and a polished look.

Common Materials Used in Manufacturing

Various applications require specific materials to meet performance needs. Steel is the most common choice because of its strength and affordability. For environments exposed to moisture or harsh conditions, stainless steel is preferred due to its excellent corrosion resistance. This makes it well-suited for outdoor, marine, and chemical applications.

In situations demanding extra toughness or reduced weight, alloy blends are selected. These materials combine different metals to enhance durability, wear resistance, or weight efficiency. Choosing the right material ensures the fastener performs reliably under the specific stresses of each use case.

Popular Head Designs and Their Functions

Hex Heads

Hexagonal heads are widely used for their ease of gripping with standard wrenches. Their shape allows quick tightening and loosening, especially in confined or hard-to-reach spaces.

Socket Heads

Socket heads feature an internal recess for Allen or hex keys, providing a clean, streamlined appearance. This design enables tightening in areas where external wrench access is limited.

Button Heads

Button heads have a low-profile, rounded shape that offers a smooth finish. They are ideal for applications where a less protruding fastener is desired for safety or aesthetic reasons.

Flat Heads

Flat heads are countersunk to sit flush with or below the surface of the material. This makes them suitable where a smooth, unobtrusive finish is required without any raised edges.

Threading Options and When to Use Them

Thread type plays a crucial role in how loads are distributed and how well a fastener resists vibration. Coarse threads are advantageous for applications requiring rapid assembly and disassembly, offering easier engagement. Fine threads provide superior tension control, making them suitable for precision and high-stress environments.

Also, some fasteners feature partial threading, combining the benefits of both. This design provides a secure grip on the threaded portion while allowing flexibility where needed. Selecting the appropriate thread type ensures optimal performance and longevity of the assembly under varying conditions.

Applications Across Different Industries

Construction Applications

These fasteners are essential in building sturdy steel frameworks and securing load-bearing joints. Their strength ensures structural stability and safety in various construction projects.

Automotive Industry

Used extensively in engines and chassis assemblies, these components provide reliable fastening under high stress. Their durability supports vehicle performance and longevity.

Electronics Use

Precision alignment makes them ideal for assembling delicate electronic parts. They help maintain tight tolerances, ensuring proper function and minimizing damage during manufacturing.

Surface Treatments and Coatings

Coatings enhance durability and environmental resistance. Zinc plating offers rust protection and a polished finish. Black oxide improves lubricity while providing minimal corrosion resistance. Specialized coatings can also improve torque consistency during installation.

Standards and Specifications to Know

Industry standards play a vital role in guaranteeing the safety and performance of fasteners. Organizations such as ANSI, ISO, and ASTM provide classifications that help buyers verify product compatibility and quality. These standards establish critical specifications, including thread pitch, tensile strength, and precise dimensional tolerances.

Compliance with these guidelines ensures that components meet required safety regulations and function reliably over time. Following established standards also simplifies sourcing and quality control, promoting consistency and trust across industries where dependable fastening solutions are essential.

Installation Tips for Best Results

Proper Tool Usage

Selecting the right tool for installation prevents damage to fasteners. Using incorrect tools can strip heads or cause uneven tightening, compromising durability.

Controlled Torque Application

Applying the correct torque level is crucial to avoid over-tightening or loosening. Proper torque ensures a secure fit without stressing the materials.

Thread Preparation

Cleaning threads before installation removes debris and contaminants. This promotes a tight, consistent connection that reduces the risk of loosening over time.

Alignment Verification

Ensuring components are correctly aligned before tightening preserves structural integrity. Misalignment can lead to uneven stress and premature failure of the assembly.

Cap Screws remain a top choice for engineers and technicians who value strength, precision, and reliability. Whether securing a vital machine part or ensuring the safety of a structural frame, they deliver results without compromise. Choosing the right material, head design, and threading can make all the difference. Their adaptability and dependability continue to make them an indispensable fastening solution across industries.